Goliath

A press with a horizontal head and buck, specifically designed for rapid, flawless pressing of trousers.

Available in 3 versions:

- PANTAMASTER - The particular construction of its twin bucks allows to finish both trousers’ legs at the same time, setting the front pleats up to 3 cm from the waistline. Its wide bucks make this machine very versatile and suitable also for finishing knitwear or blankets. Trousers are put on the lower buck and held by a special waistband auto-sizing locking device which sets the pleats. Following this, the semi-rigid frame is lowered allowing the second leg to be laid on the buck. The pressure of the head completes the pressing operation.

- Lower buck with live steam, vacuum and air-blowing upon request

- Upper buck with live steam

- Built-in vacuum motor

- Pneumatic-clamping device for waistline locking

- Electronic board with 10 memorized programs

- Automatic cycle when closing the upper buck

- Ready for connection to external steam and air supplies.

- PANTAMASTER HQ - Same as Pantamaster with the addition of a heated, air-blowing topper for a very accurate quality of finishing.

- DLP-DOUBLE LEGGER PRESS (new) – universal legger press, equipped with automated ironing cycle and intermediate separation frame for the finishing of the second leg:

- Lower buck with live steam, vacuum and air-blowing upon request

- Upper buck with live steam

- Built-in vacuum motor

- Electronic board

- Ready for connection to external steam and air supplies.

- 9 or 20 litters boiler

- Blowing device for the lower buck

- Steam iron assembly and safety device.

Inox 16

Electric steam generators with ball-cock water level control. The electric steam generators of the INOX series, with the body of the boiler entirely made of STAINLESS STEEL AISI 304, are produced in accordance with the PED regulations. The steam generator can be fed directly by the water supply network or by a special steel tank.

The INOX series is available with boilers of different sizes and different power:

- INOX 16, boiler volume 16 lts, and stainless-steel electric heating elements of 7-8-10-12-15 Kw

- INOX 24, boiler volume 25 lts, and stainless-steel electric heating elements of 6-7-8-10-12-14-15-16-18-20-22 kW, with a unique group of heating elements or two groups.

- INOX 60, boiler volume 55 lts, and stainless-steel electric heating elements of 20-24-30-36-40-50- 60 kW, with two groups of heating elements.

- INOX 60 COMBI is composed by two overlapping INOX 60 boilers which can be used at the same time

- INOX 180, composed of three overlapping INOX 60 boilers that can be used at the same time

- Stainless steel tank for water feeding and condensate recovery

- all tank components in contact with water made in stainless steel.

Inox 24

Electric steam generators with ball-cock water level control. The electric steam generators of the INOX series, with the body of the boiler entirely made of STAINLESS STEEL AISI 304, are produced in accordance with the PED regulations. The steam generator can be fed directly by the water supply network or by a special steel tank.

The INOX series is available with boilers of different sizes and different power:

- INOX 16, boiler volume 16 lts, and stainless-steel electric heating elements of 7-8-10-12-15 Kw

- INOX 24, boiler volume 25 lts, and stainless-steel electric heating elements of 6-7-8-10-12-14-15-16-18-20-22 kW, with a unique group of heating elements or two groups.

- INOX 60, boiler volume 55 lts, and stainless-steel electric heating elements of 20-24-30-36-40-50- 60 kW, with two groups of heating elements.

- INOX 60 COMBI is composed by two overlapping INOX 60 boilers which can be used at the same time

- INOX 180, composed of three overlapping INOX 60 boilers that can be used at the same time

- Stainless steel tank for water feeding and condensate recovery

- all tank components in contact with water made in stainless steel.

Inox 60

Electric steam generators with ball-cock water level control. The electric steam generators of the INOX series, with the body of the boiler entirely made of STAINLESS STEEL AISI 304, are produced in accordance with the PED regulations. The steam generator can be fed directly by the water supply network or by a special steel tank.

The INOX series is available with boilers of different sizes and different power:

- INOX 16, boiler volume 16 lts, and stainless-steel electric heating elements of 7-8-10-12-15 Kw

- INOX 24, boiler volume 25 lts, and stainless-steel electric heating elements of 6-7-8-10-12-14-15-16-18-20-22 kW, with a unique group of heating elements or two groups.

- INOX 60, boiler volume 55 lts, and stainless-steel electric heating elements of 20-24-30-36-40-50- 60 kW, with two groups of heating elements.

- INOX 60 COMBI is composed by two overlapping INOX 60 boilers which can be used at the same time

- INOX 180, composed of three overlapping INOX 60 boilers that can be used at the same time

- Stainless steel tank for water feeding and condensate recovery

- all tank components in contact with water made in stainless steel.

Inox 60 Combi

Electric steam generators with ball-cock water level control. The electric steam generators of the INOX series, with the body of the boiler entirely made of STAINLESS STEEL AISI 304, are produced in accordance with the PED regulations. The steam generator can be fed directly by the water supply network or by a special steel tank.

The INOX series is available with boilers of different sizes and different power:

- INOX 16, boiler volume 16 lts, and stainless-steel electric heating elements of 7-8-10-12-15 Kw

- INOX 24, boiler volume 25 lts, and stainless-steel electric heating elements of 6-7-8-10-12-14-15-16-18-20-22 kW, with a unique group of heating elements or two groups.

- INOX 60, boiler volume 55 lts, and stainless-steel electric heating elements of 20-24-30-36-40-50- 60 kW, with two groups of heating elements.

- INOX 60 COMBI is composed by two overlapping INOX 60 boilers which can be used at the same time

- INOX 180, composed of three overlapping INOX 60 boilers that can be used at the same time

- Stainless steel tank for water feeding and condensate recovery

- all tank components in contact with water made in stainless steel.

Jolly

Professional COLD and STEAM spotting tables are ideal to remove any kind of stain in both the dry-cleaning and garment industries, for the treatment of stains deriving from different production stages.

Available in two versions:

JOLLY - Cold spotting table. Features: Stainless steel board and sleeve spotting arm. Garment tray. Cooling coil. Two spotting guns and two tanks for liquid spotting agents. Air drying gun. Available with built-in vacuum unit or ready for connection to central vacuum supply.

Available options:

- Suction cap either ready for external exhaust or with activated carbons filter

- Built-in compressor

- Steam and air gun assembly.

- Built-in vacuum unit

- Water spray gun with condenser

- Cold spotting gun with tank for spotting agents

Kappa

This cabinet is the ideal solution to improve the quality of your dry-cleaning This compact and functional unit ( 100x85 cm ) offers in a reduced space both pre -and post -spotting facilities . KAPPA is built from high grade stainless steel, and meets the modern requirements for protection of the environment thanks to the built-in powerful suction fan and ecological active carbon filtration set.

Pre-spotting unit includes:

one 5 liter pressurized soap tank, stainless steel, with soap spray gun.

Post-spotting unit includes:

two independent pivoting stainless steel spotting bucks cold spotting gun with tank and support. Air drying gun.

Available in three versions:

- KAPPA 1: PRE - spotting and POST-spotting unit.

- KAPPA 2: PRE - spotting unit.

- KAPPA 3: basic unit for POST spotting, (without guns, to be selected time by time according to the different needs).

- Steam/Air gun.

- Automatic electronic steam boiler.

- Soap tank with spray soap guns.

- Cold spotting gun.

Kite

KITE is the latest evolution in shirt finishers from PONY, suitable for the finishing of shirts, polo shirts, chef’s jackets and medical uniforms.

Thanks to its solid construction and advanced design, KITE provides the user an excellent finishing quality as well as very high productivity.

The advanced design ergonomics of this machine has resulted in the introduction of the exclusive front sliding paddle which results in easy, fast dressing of the shirt without any obstacles between the operator and the shirt being processed.

With this brand new model, PONY aims to offer its customers the best quality to price ratio in its class, whilst incorporating some of the advanced features found in the more expensive models in the range.

KITE is available both in steam or electric versions. Thanks to bespoke software and meticulous engineering, KITE in the electric version can operate with only 9.85 Kw of electric power in the ECO mode.

KITE STANDARD EQUIPMENT INCLUDES:

- SMALL DUMMY - which allows the finishing of a wide range of sizes;

- sliding FRONT PADDLE (to ease the dressing of the shirt) with silicon padding to avoid button marks and shining on dark fabrics;

- manually height adjustable pneumatic SLEEVE TENSIONING CLAMPS with oval-shaped sleeve locking device, suitable for ironing short and long sleeves;

- patented H.A.R.S. TECHNOLOGY which allows the recapture of hot air from the shoulder press, reducing the cycle time and energy consumption;

- PLC TOUCH SCREEN providing customized management of all functions, finishing cycles, single operator’s productivity, diagnostics, software updates and auto-test. When connected to a router through an Ethernet port or via WI-FI, it allows these functions to be carried even from a remote location;

- KITE is height adjustable and is equipped with a mirror.

- STANDARD dummy;

- remote control EASY ACCESS 2.0 Ethernet or WI-FI;

- electric iron for touch-ups.

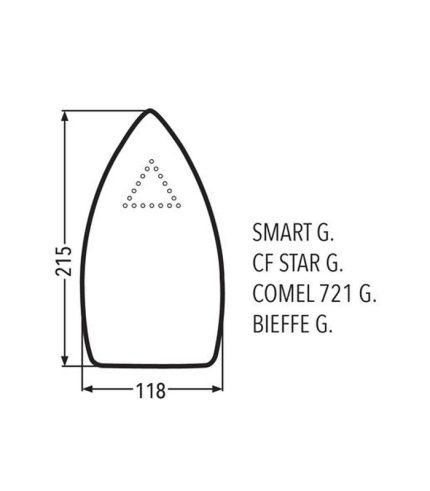

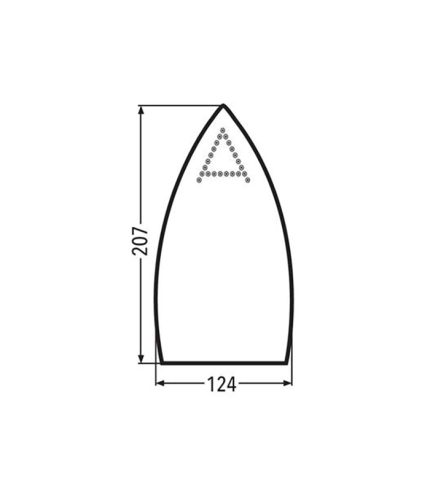

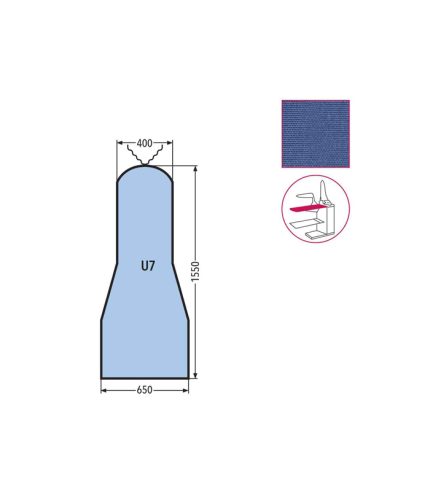

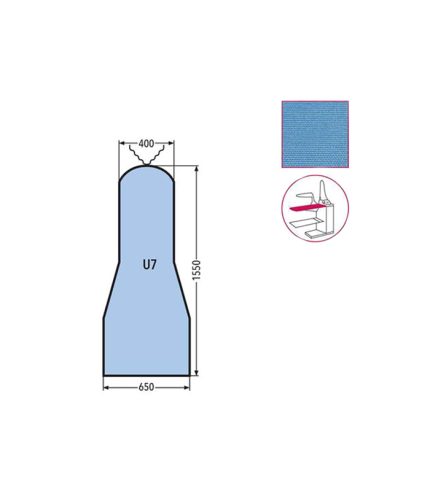

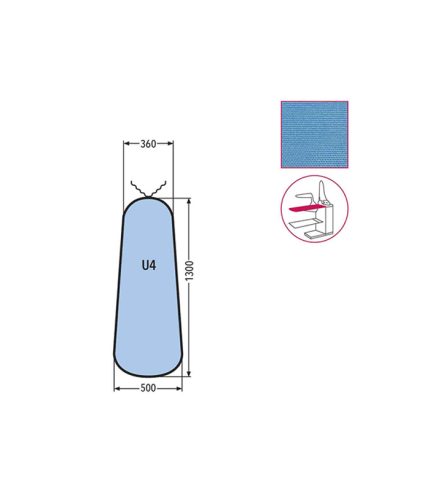

LAV PRESS

Air-operated finishing presses for wet garments. Nickel-plated POLISHED steam-heated head, steam-heated lower buck WITHOUT VACUUM, adjustable squeezing pressure. 50° head opening. Available self-contained or ready for connection to external steam and air supplies.

Available in different shapes:

- LAV/U Utility shape

- LAV/UP Utility legger shape

- LAV/P Legger shape

- LAV-R1/E rectangular shape and electrically heated lower buck, vacuum upon request

- LAV-R1/V rectangular shape

- LAV-R2/E rectangular Lab-coat Shape and electrically heated buck, vacuum upon request

- LAV/BB Body Bosom shape

- LAV/F Mushroom shape

- CCP collar and cuff press with electrically heated lower buck with vacuum

- 7 or 20 litters boiler Built-in vacuum

- Built-in compressor

- Water spray gun

- Adjustable head-release timer

- Steam iron assembly with an electric steam iron or ALL STEAM iron with or without safety device.

MG

The form finisher’s range MG has been engineered to meet the demand for blow finish for all outerwear in dry cleaning and laundry stores, the garment industry, ironing services, and the hospitality industry.

Features are: Finishing cycles controlled by a microprocessor with 10 stored programs, manual cycle start or automatic cycle start using a foot pedal, adjustable hot air flow, revolving or fixed dummy if combined with the sleeve tensioning group.

Form finishers of this range are available in the following versions:

- MG: form finisher to be connected to the external steam supply. Available with Standard Dummy or with RM dummy with manual size regulations

- MGP “PNEUMATIC”: former to be connected to external steam supply with pneumatic steam valve. Available with a Standard dummy and also with a stainless-steel body.

- MGE “ECONOMO”: Former for connection to external steam supply, returning its steam condensate into an electric boiler with a minimum water level not higher than 35 cm. from the floor.

- ” MGT” sleeve tensioning assembling specifically studied for the finishing of anoraks and jackets

- 9- or 20-liters boiler

- GFV group with steam iron

- steam gun

- water spray gun

- 1,7 HP fan

- special dummies as alternative to standard dummy